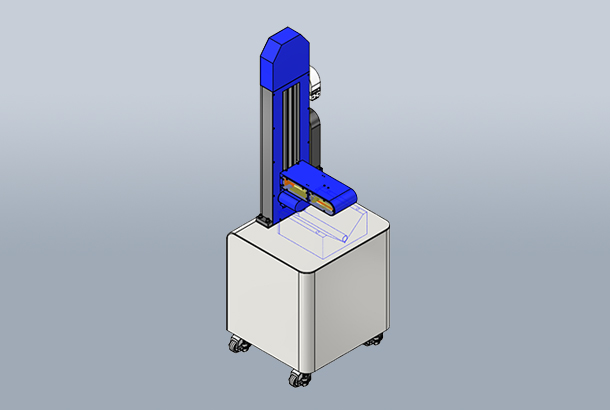

CNC FLANGE MARKING M/C

View Details· Product Features

- Marking quality remains identifiable even after various post-treatments (painting, plating, painting after plating, special coatings, etc.)

- A proven and stable product, independently developed by a piping manufacturer with 25 years of experience and verified through 3 years of testing

· Product Details

- Mass production system capable of handling various marking input values

- User-friendly operation using Excel and proprietary software

- Precise marking with a 3-axis system and high efficiency at varying speeds

- Specialized equipment for circular flange marking

| Flange diameter to be proceed | 15A~450A |

|---|---|

| Flange thickness | 28mm MAX |

| Machine length | 1,100mm |

| Machine Main unit height | 2,024mm |

| Machine Main unit width | 660mm |

| Machine weight | 350kg |

| Marking Header | 1set |

|---|---|

| (1) 2Axis | X/Y Stepping Motor |

| (2) Marking Scope | Height : 170mm, Width : 200mm |

| (3) Marking Pin | 1ea |

| (4) Marking Speed | Average of one initial mark per 0.8 seconds |

| Laser sensor system | 1set |

| System of torch travel | Motor Type |

| Primary power source | 220VAC, 1Φ 50/60Hz 10Amp Max |

| Grounding | Installation |

CNC SLEEVE & S/Q FLANGE & NAME PLATE MARKING M/C (CSM-A200)

View Details· Product Features

- Marking quality remains identifiable even after various post-processes (painting, plating, painting after plating, special coatings, etc.)

- A stable and proven product, independently developed by a piping manufacturer with 25 years of experience and verified through 3 years of testing

· Product Details

- Mass production of various products capable of handling diverse marking inputs

- Easy operation for anyone using Excel and proprietary software

- Precise marking with a 3-axis system and high efficiency at different speeds

- Specialized equipment for marking sleeves, square flanges, and square nameplates

| Flange diameter to be proceed | 15A~450A |

|---|---|

| Flange thickness | 28mm MAX |

| Machine length | 1,100mm |

| Machine Main unit height | 2,024mm |

| Machine Main unit width | 660mm |

| Machine weight | 350kg |

| Marking Header | 1set |

|---|---|

| (1) 2Axis | X/Y Stepping Motor |

| (2) Marking Scope | Height : 170mm, Width : 200mm |

| (3) Marking Pin | 1ea |

| (4) Marking Speed | Average of one initial mark per 0.8 seconds |

| Laser sensor system | 1set |

| System of torch travel | Motor Type |

| Primary power source | 220VAC, 1Φ 50/60Hz 10Amp Max |

| Grounding | Installation |

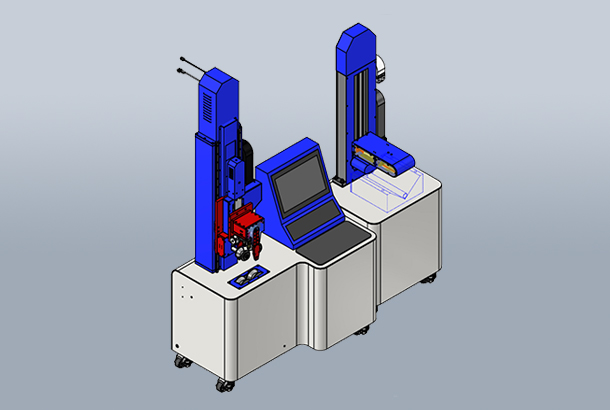

MULTIPLE CNC MARKING M/C (MCM-A450)

View Details· Product Features

- Marking quality remains identifiable even after various post-processes (painting, plating, painting after plating, special coatings, etc.)

- A stable and proven product independently developed by a piping manufacturer with 25 years of experience and verified through 3 years of testing

· Product Details

- Mass production of various products capable of handling diverse marking inputs

- Easy operation for anyone using Excel and proprietary software

- Precise marking with a 3-axis system and high efficiency at varying speeds

- One machine capable of marking round flanges, sleeves, square flanges, and square nameplates

| Flange diameter to be proceed | 15A~450A |

|---|---|

| Flange thickness | 28mm MAX |

| Machine length | 1,100mm |

| Machine Main unit height | 2,024mm |

| Machine Main unit width | 660mm |

| Machine weight | 350kg |

| Marking Header | 1set |

|---|---|

| (1) 2Axis | X/Y Stepping Motor |

| (2) Marking Scope | Height : 170mm, Width : 200mm |

| (3) Marking Pin | 1ea |

| (4) Marking Speed | Average of one initial mark per 0.8 seconds |

| Laser sensor system | 1set |

| System of torch travel | Motor Type |

| Primary power source | 220VAC, 1Φ 50/60Hz 10Amp Max |

| Grounding | Installation |