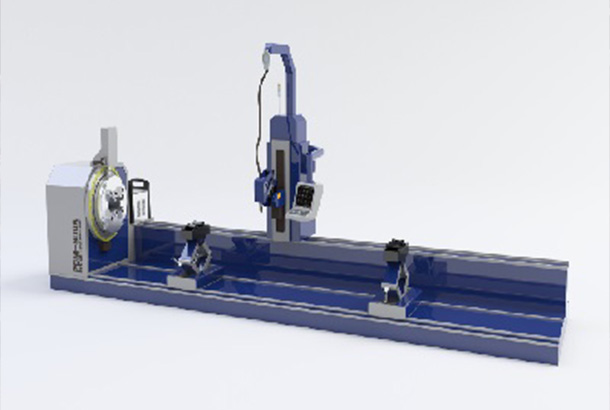

PCM-B800

View Details· Product Features

- Developed in a Windows environment for easy accessibility and convenient after-sales service.

- Allows recipe-based configuration instead of traditional CAM-based operations, simplifying data setup.

- Developed using servo control technology for precision and stability.

· Product Details

- Equipped with a 19" PC touch display

- Standardized UI by pipe shape model

- Designed for cutting various pipe shapes used in shipbuilding, marine, and plant industries

| Pipe diameter to be proceed | 25A~800A |

|---|---|

| Pipe Thickness | Oxy-fuel cutting : 10~120mm, Plasma : 1~25mm |

| Torch rail length | 5,950mm |

| Max. weight of pipe | 3,000kg |

| Machine length(L) | 7,300mm |

| Machine Main unit height(H) | 2,249mm |

| Machine Main unit width(W) | 1,655mm |

| Machine weight | 6,500kg |

| Pipe chunk | 4 jaw |

|---|---|

| (1) Diameter of chunk | 830mm |

| (2) Clamping system | Manual / Automatic Operation, Automatic: Uses a motor for clamping and unclamping |

| Control box including computer system | Operation panel 1set |

| Plasma cutting machine ; Model Name | Hypertherm Powermax 125 |

| Automatic Oxy-fuel preheat torch | Preheating torch 1set |

| System of torch travel | Servo Motor System |

| Primary power source | 380VAC, 3Φ 50/60Hz 70Amp Max |

| Grounding | Installation |

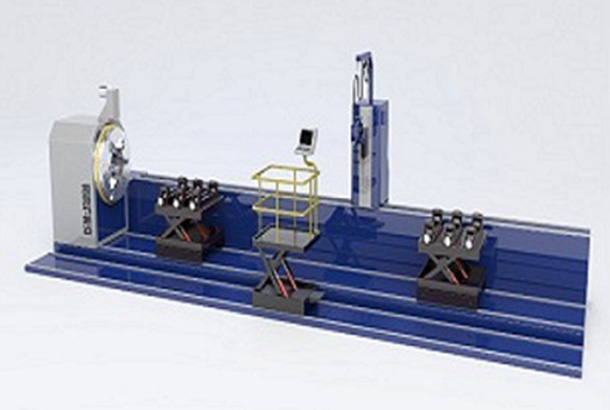

PCM-A1500

View Details· Product Features

- Equipped with a touch panel control system, offering intuitive operation through icon-based visual interface

- Allows saving of work recipes for easy retrieval and reuse during repetitive tasks

· Product Details

- Features Chuck Up/Down functionality with a Screw Jack System, enabling easier pipe clamping

- Equipped with a Hydraulic Pipe Lift for precise height adjustment (Vertical movement: hydraulic / Horizontal movement: motor-driven)

- Includes a Hydraulic Operator Lift for convenient working position control (Vertical movement: hydraulic / Horizontal movement: motor-driven)

| Pipe diameter to be proceed | 25A~800A |

|---|---|

| Pipe Thickness | Oxy-fuel cutting : 10~120mm, Plasma : 1~25mm |

| Torch rail length | 5,950mm |

| Max. weight of pipe | 3,000kg |

| Machine length(L) | 7,300mm |

| Machine Main unit height(H) | 2,249mm |

| Machine Main unit width(W) | 1,655mm |

| Machine weight | 6,500kg |

| Pipe chunk | 4 jaw |

|---|---|

| (1) Diameter of chunk | 830mm |

| (2) Clamping system | Manual / Automatic Operation, Automatic: Uses a motor for clamping and unclamping |

| Control box including computer system | Operation panel 1set |

| Plasma cutting machine ; Model Name | Hypertherm Powermax 105 |

| Automatic Oxy-fuel preheat torch | Preheating torch 1set |

| System of torch travel | Servo Motor System |

| Primary power source | 380VAC, 3Φ 50/60Hz 70Amp Max |

| Grounding | Installation |